Strategic Metals for the Lowest Cost

Proven. Scalable. Zero-Emissions.

World's Cleanest and Fastest Method to Make Metals.

World's Cleanest and Fastest Method to Make Metals.

Zinc • Silver • Gold • Copper • Indium • Gallium/Germanium

World's Cleanest, Fastest, and Most-Profitable Method to Process Sulfide Mineral Concentrates and Make Metals

Green technology. Developed over 25 years of actual experience processing complex sulfide concentrates and producing pure metals, the modern Metalox Process is powerful, low-cost, and clean.

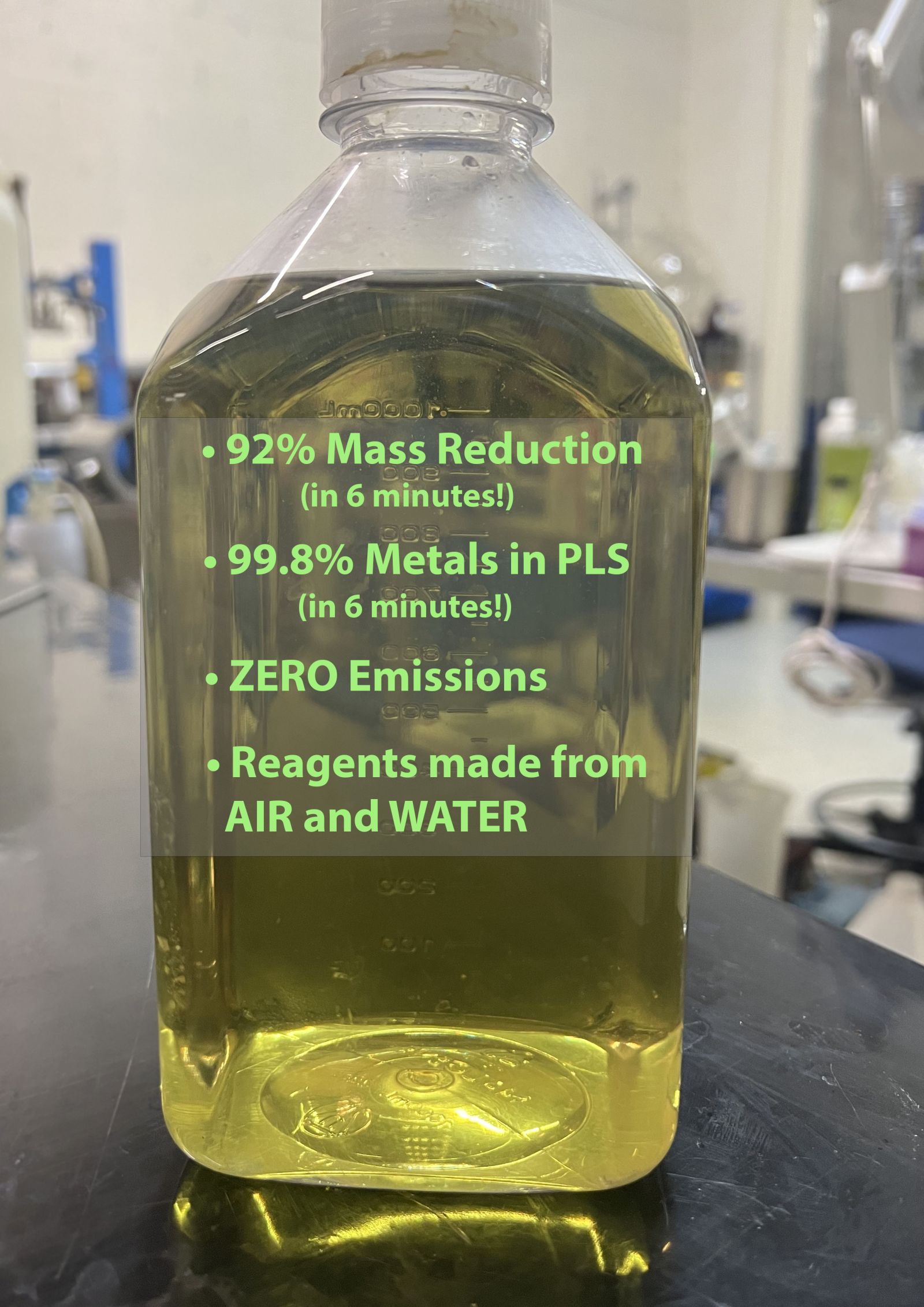

Fastest Digestion Known to Science. Metalox is the fastest, lowest-cost, and highest-recovery method to extract metals from sulfide concentrates––period. Proven time and time again with all types of complex sulfides, Metalox can process concentrates that no traditional smelter or hydrometallurgical plant can handle. No competing commercial hydrometallurgical method even comes close. Only 10 minutes from solid concentrate to 99% extraction of the soluble metals, such as silver, zinc, copper, and indium. The insoluble metals (gold, lead) are filtered, recovered, and purified at near 100% efficiency. In most cases, we can process concentrates with zero solid waste, zero gases, and zero liquid discharge.

No fine grinding. Run of mill concentrates--all mesh sizes, from +18 to -200––Metalox processes coarse or fines. No other method offers such flexibility.

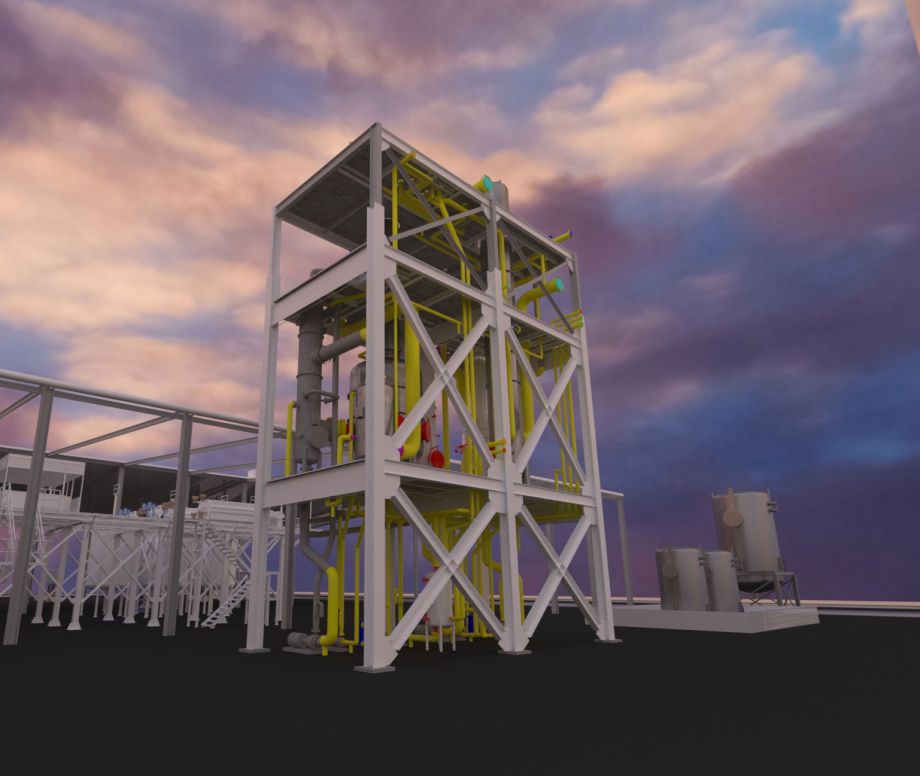

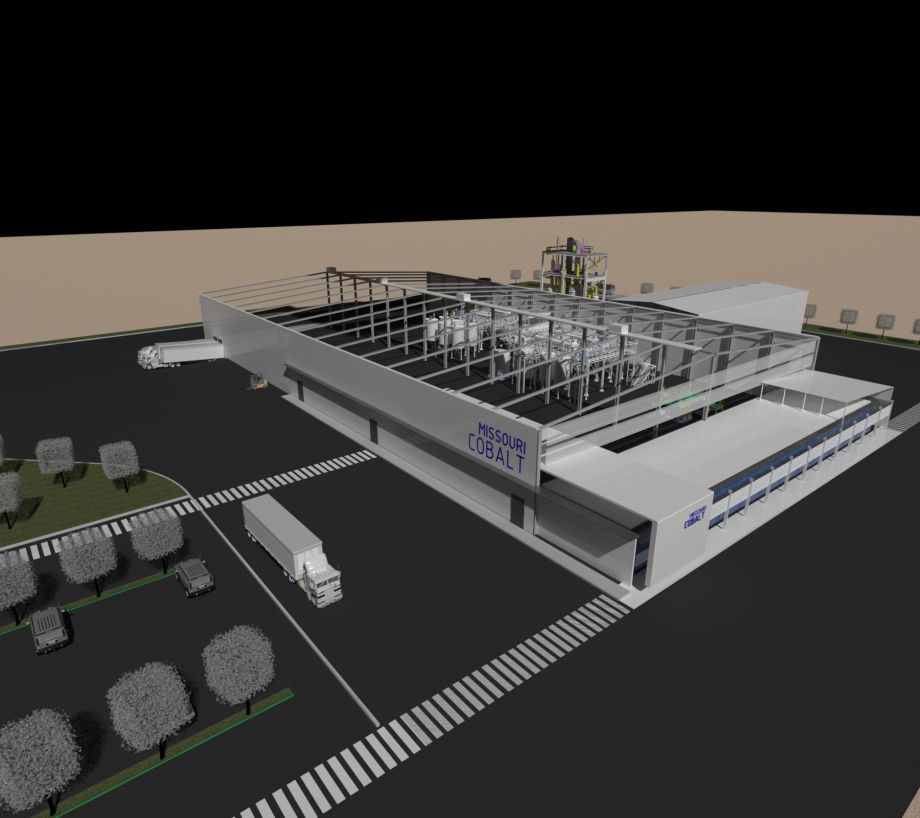

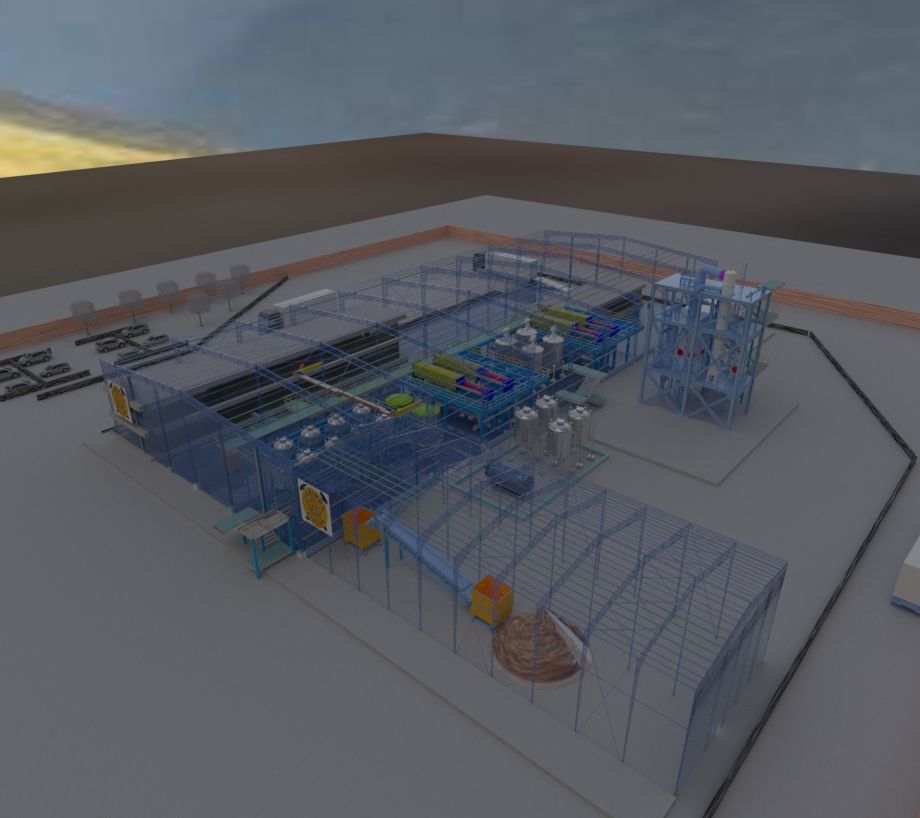

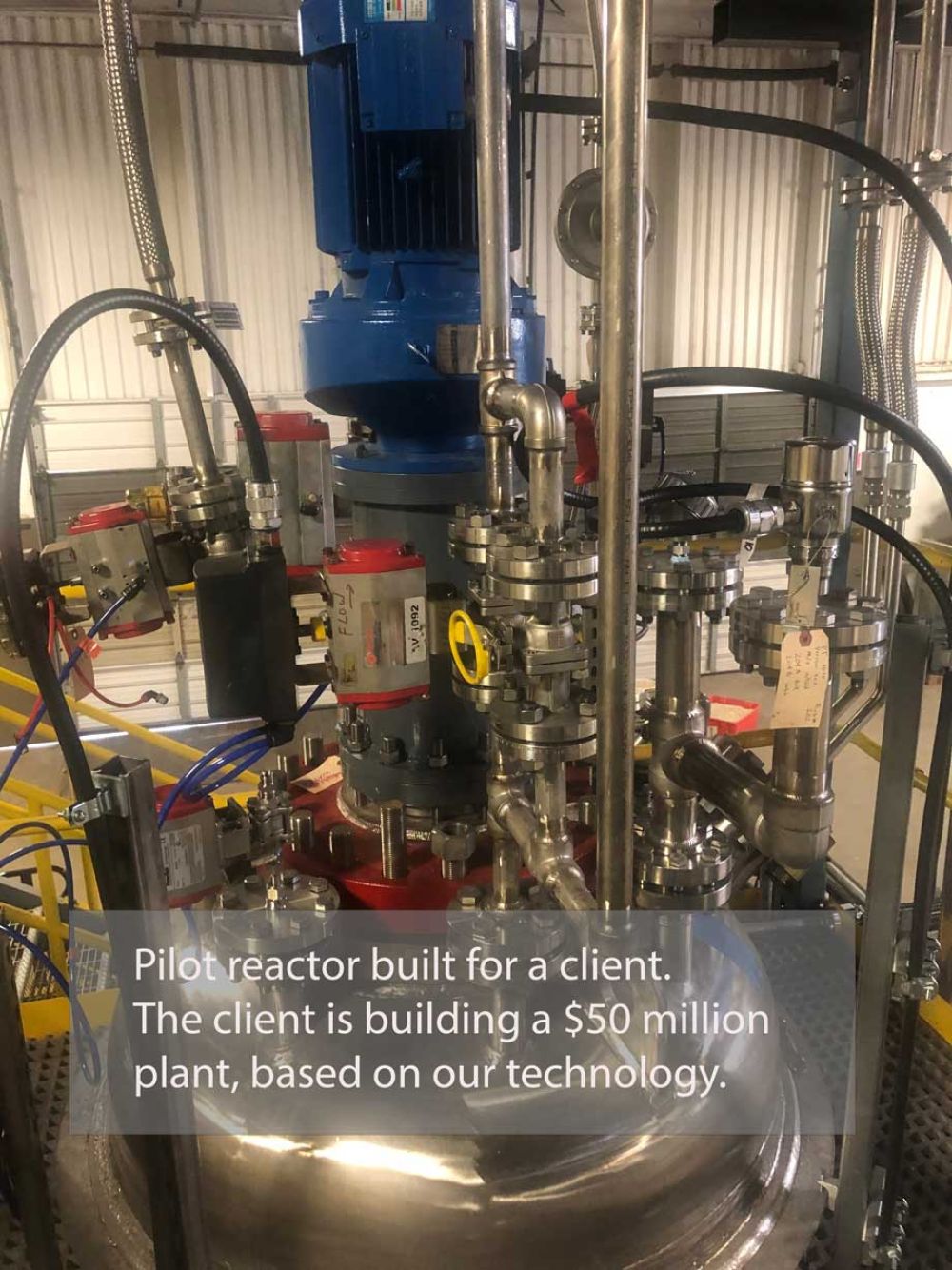

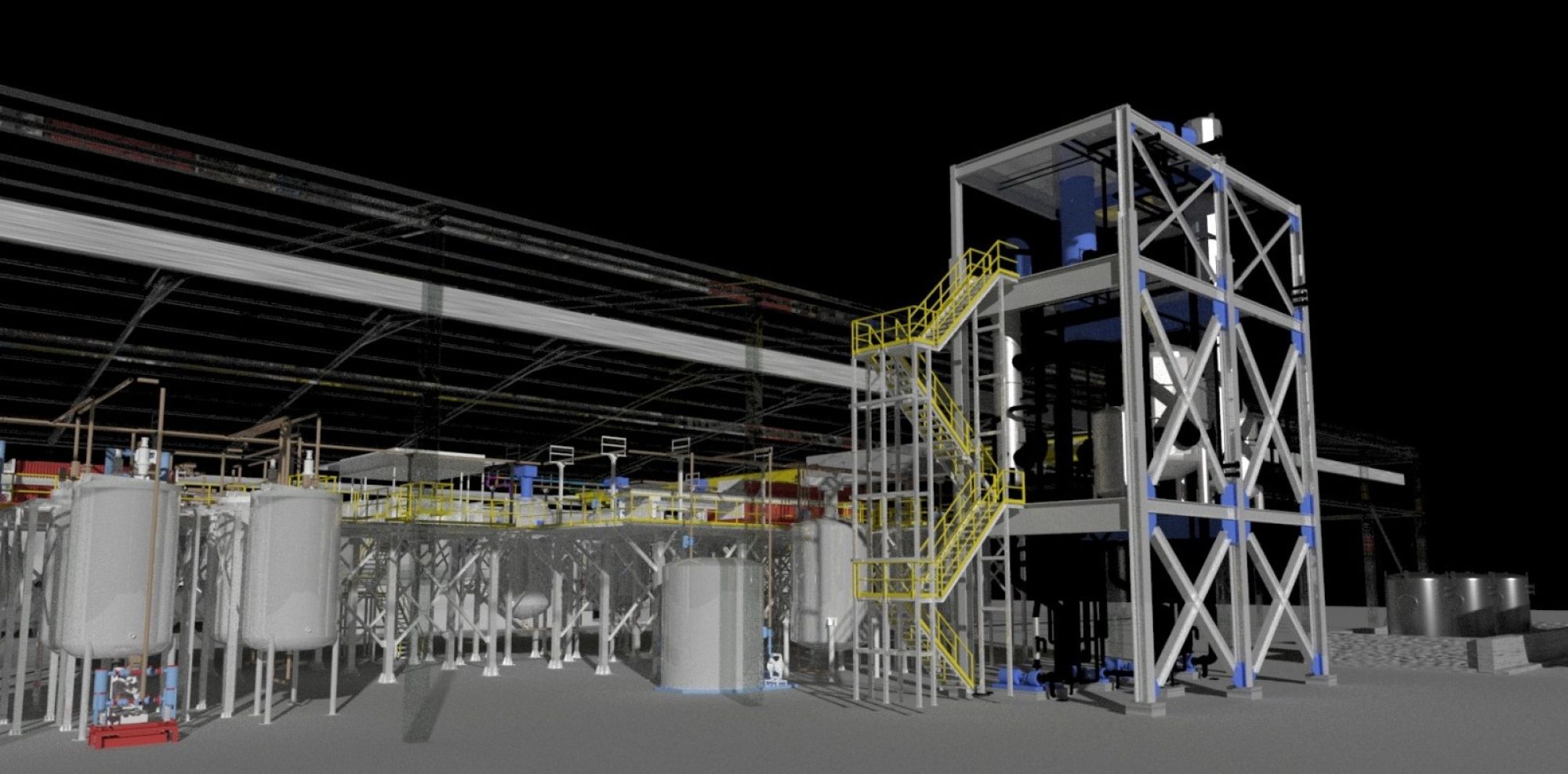

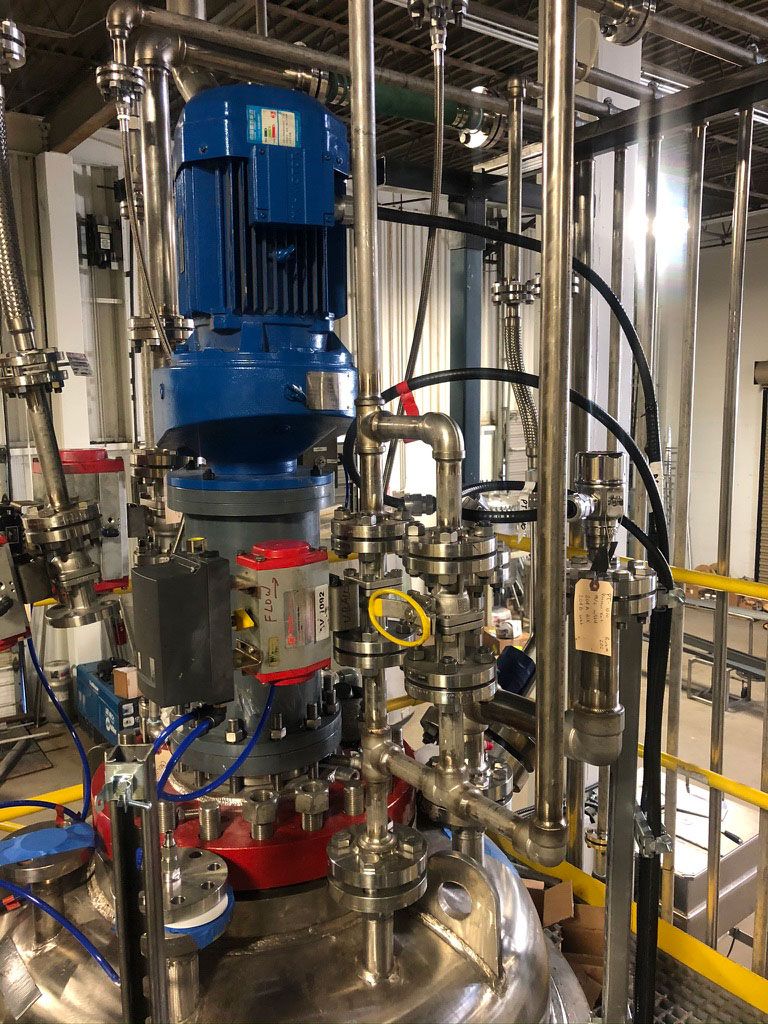

Seeing is believing. We can prove it today. Our laboratory is fully-equipped with custom-designed reactors and top-of-the-line analytical instruments. We can deliver a complete metallurgical work-up in weeks (where other research labs take months). In the near future, our 3 TPD pilot plant (currently under construction) will showcase our technology, from raw concentrate to pure metals and pure by-products. Our proven technology is scalable, modular, highly efficient, low-cost, and absolutely clean.

Combined with solar power, plus a source of green hydrogen, the Metalox Process would become the world's first, absolutely carbon-free, zero emissions, totally green method to produce metals in the 21st century––offering metals and by-products that can be certified as zero carbon emissions to a world-wide consumer base.

A Clean, Profitable Leach Method

Our breakthrough process offers advantages over other hydrometallurgical methods to extract metals from mineral concentrates.

We offer:

- Zero emissions, zero waste

- Lowest cost, highest profitability

- Fastest build

- Highest efficiency in metals recovery

- Lowest energy consumption per ton of metal

- Best return on investment

- 100% Integration with Green Hydrogen

Seems like Magic––based on Science

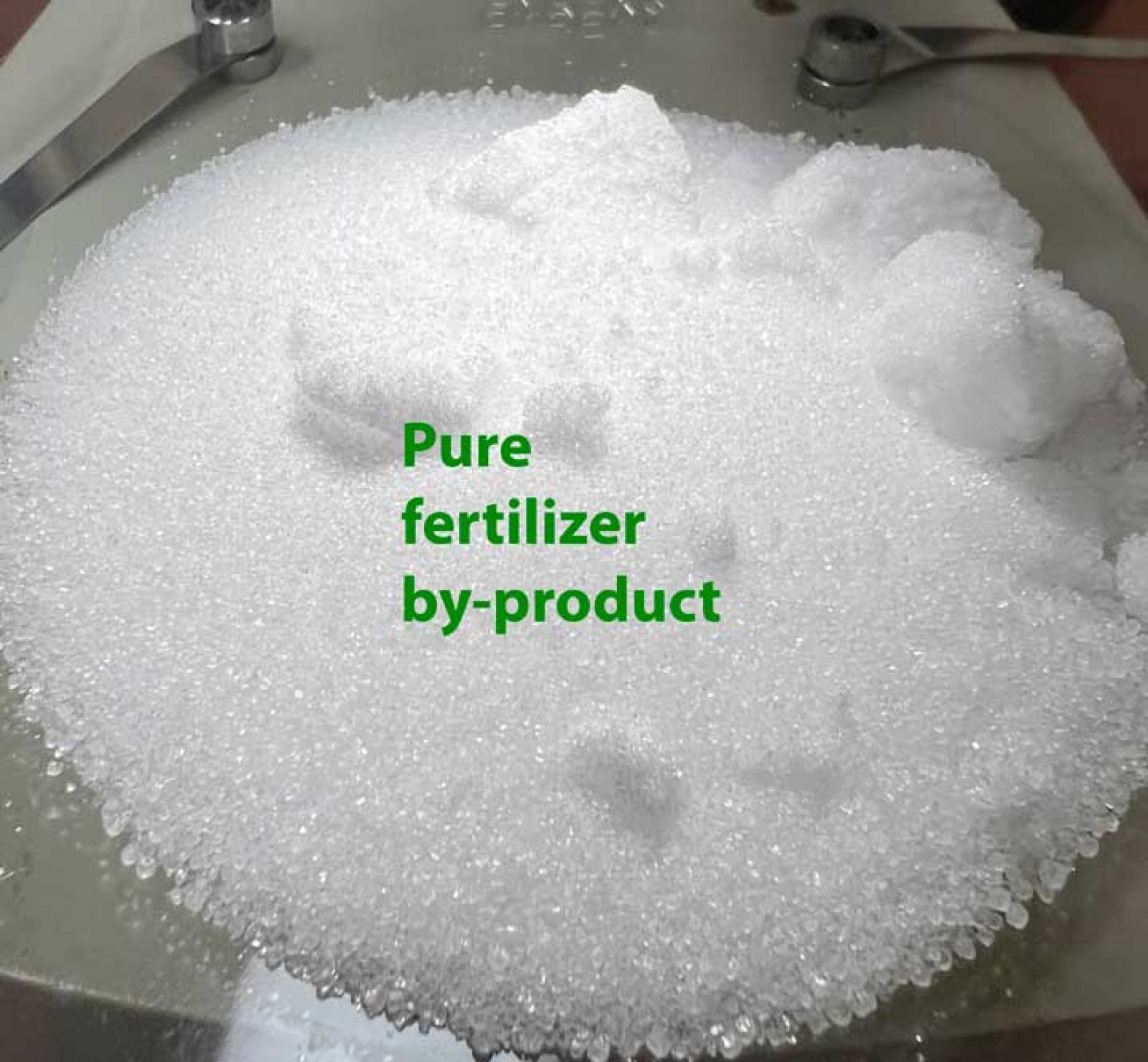

So fast, it has to be seen to be believed. Total oxidation of any sulfide mineral concentrate in 10 minutes. 99% solubility. Up to 92% mass reduction. Using only water, oxygen, and a catalyst to extract 99.7% of Zinc, Silver, Indium, Copper, and other metals in the fastest digestion reaction known to science. After filtration, nitrogen compounds precipitate the metals, one-by-one--which are then washed, and converted to value-added compounds. Different downstream methods are used to refine metals. Chemical inputs are recovered as high-quality nitrogen fertilizers, thereby lowering operating costs to a minimum. Water is 100% recycled. Depending on the concentrate, little or no solid waste would require disposal. The entire process can be Zero-Liquid-Discharge and Zero-Emissions.

METALOX is Green!

Metalox is the ONLY metallurgical method that 100% integrates into the green, zero-carbon future. Our next project will use Concentrated Solar Power (CSP) to make process heat and green hydrogen (from which the catalyst and downstream chemicals can be made, using only air and water) to process concentrates. We plan to offer the world's first source of green metals and green fertilizers with zero liquid discharge, zero emissions, and zero GHG!

DEMONSTRATION FACILITY IN FLORIDA

Demonstration Facility

Our demonstration facility in Florida is available to perform full process development of clients' concentrates. We have pressure reactors, pressure filters, and a well-equipped analytical lab for complete work-ups.

Analytics include a Perkin Elmer ICP and a top-of-the-line ED-XRF for instant confirmation of results. The demonstration facility allows stake-holders to witness in person how the Metalox process can extract metals from sulfide concentrates with zero emissions, using only water, catalyst, and oxygen.

Specialized Expertise

- Catalyzed Digestion of Sulfides in Proprietary-Designed Reactors

- Pressure filtration to emulate commercial equipment, including centrifugal separation

- Downstream recovery of pure metals, using a single reagent family to preclude unwanted elements in the pure by-product fertilizers

- Instant assays using research-grade ED-XRF and ICP

- World-class Gold and Silver Refining Experience

Metalox has developed the cleanest, fastest and lowest-cost hydrometallurgical method to extract metals from sulfide mineral concentrates. Our method offers the highest recovery for the lowest capital cost.